Water isn’t manufactured, yet from the moment raw water at its source enters the treatment process until it’s later consumed, the water purveyor has the same operating cost, quality, reliability, sourcing and delivery issues to consider as does any manufacturing operation.

Installing Mueller® brand products provides the advantage of proven designs and superior performance and reliability. Mueller Co. and its Henry Pratt subsidiary make the various valves and controls necessary for the reliable control of water as it passes through the treatment plant and into the water mains. With more than 150 years of waterworks experience behind them, flow control products bearing the Mueller® brand name assure many decades of dependable service. Once gathered from a lake, river, reservoir or deep well, the waterworks treats the raw water to improve its quality. This filtering and purifying is done using several possible procedures:

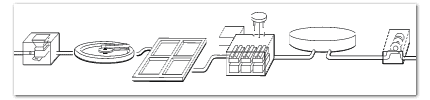

Mixing

Chlorine and other purifying chemicals are added to the raw water by automated equipment.

Flocculation

Fine particles of foreign matter are removed in a flocculator through the formation of gelatinous masses.

Sedimentation

In sedimentation tanks, water is held while the masses of fine particle or “floc” settle to the bottom. Clear water is drawn off the top of the tank.

Filtration

The water is passed slowly through a porous sand filter or membrane that removes minute particles and improves taste, color and purity.

Clear-well Storage

Large reservoirs and storage tanks provide reserves of water and help maintain pressure throughout the distribution system.

High-lift Pumping

Powerful pumps constantly maintain pressure and flow of finished water to all parts of the water system. In the pump house, resilient-seated gate valves and butterfly valves control water flow. Check valves automatically assure flow in one direction.